When looking at the requirements for the box project, I thought of pecked paper and silhouette work used when making designs on the medium. When looking for references, I remembered the use of pecked paper during Day of the Dead and the skulls that are designed, so I decided to use them as the main image of the box lamp. I used a skull silhouette as the direct reference for the image, making slight changes to make the image more symmetrical. Additionally, I removed some of the detail so as to avoid the wood burning from too much heat, as my initial design that had more holes was a failure. Because of the vibrancy of the skulls, I decided to paint each side with variations of the same color palette and paint the background black to have them stand out more. To make painting easier, I placed the engraving lines in a way that would make painting easier around the more complicated areas while cutting out holes in areas that would be hollow in a skull, such as the eyes and nose area.

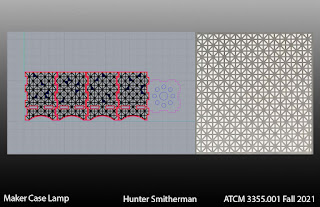

Using Maker Case, I created a 4-sided box with an opening at

the top measuring 4 inches by 6 inches. I made sure that Rhino was configured and

laid out the Maker Case curves. I added a curve to the bottoms of the walls to make

legs for the lamp. To add the skull design, I made the lines in Adobe

Illustrator and imported the designs as curves. After centering the design on

each of the front sides, I made some slight layer changes to the curves. I

changed the outline of the skull to a medium vector engrave while leaving the

rest of the adornments as light vector engraves. The inner cuts of the eyes and

nose were not changed. Once the curves were complete, I extruded the curves and

used the Boolean Subtract function to make the holes. For the engravings, the Boolean

Subtract and Offset functions continuously failed for portions of the engravings,

so I worked around it but slightly extruding out of the model and using the camera

angle to fake the indentions uniformly, especially for the KeyShot render. It until after I had rendered that I found naked edges to be the problem. While I did not re-render and kept the fake engrave, I did fix the naked edges afterwards.

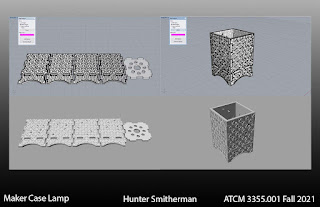

Within KeyShot, I customized the walnut wood preset to make it lighter and rougher. Next, I added five paint labels: four of the labels were the painted skulls while the last label was a black rectangle for the painted background. Each of the labels was given a wood bump map to create the wooden surface of the lamp.

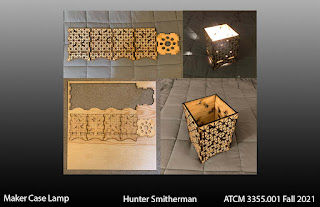

For the physical object, I sanded each of the pieces to

create a smooth surface. Next, I painted each of the skulls with a variation of

a chosen color palette. Once each of the skulls was painted, I painted the

backgrounds black to help the skulls stand out. After the painting was finished,

I applied multiple layers of wood finish to each of the painted sides. After each

coat of finish, I lightly sanded the surface for a better application. Once the

paint was sealed, I placed the light socket into the center bottom hole and assembled

the lamp with Loctite glue. Once assembly was complete, I placed the lightbulb in

and turned it on. I’m very happy with how the lamp turned out despite some of

the issues caused by the wood being hollow in certain areas. I’m glad that I decided

to paint the skulls differently, as it makes the lamp feel more vibrant.

The wood used was a 2’ by 4’ sande plywood with a thickness

of a quarter inch. The wood was painted on with acrylic paint. The paint and

wood were sealed with a spar urethane wood finish. The lighting of the lamp is

made with a 25-watt light bulb connected to an E12 socket base and cord. For the

renders in KeyShot, I used the interior lighting preset as I felt that it lit

the model the best. I made sure to angle the model in a way to display the wood

grain subtly and make the illusion of engravings.