For the LED Sleeve in Week 5, the design was kept simple.

The design features a grip on the handle with several subtle accents.

Features include ridges, which were created using the 'chamfer' and 'fillet' commands, as well as 5 pyramid-shaped notches, arrayed around the center of the sleeve. The notches were created using the 'booleanDifference' command. Although it is simple, the goal was see how the design would turn out 3D printed before going too elaborate. With any luck the next model will utilize more features with more comfort-ability in the 3D printing process. I am curious to see the full potential of the 3D printing lab.

Rhino - screenshot #1

Essentially the design was split into three parts- the main body (or shaft), the grip, and the accented notches.

Rhino - screenshot #2

Here the NURBS model created above has been exported to a STL file, which is submitted to the lab to be 3D printed.

Keyshot #1

Here the sleeve is laying on its side, at an angle which the viewer can see the cut-away notches.

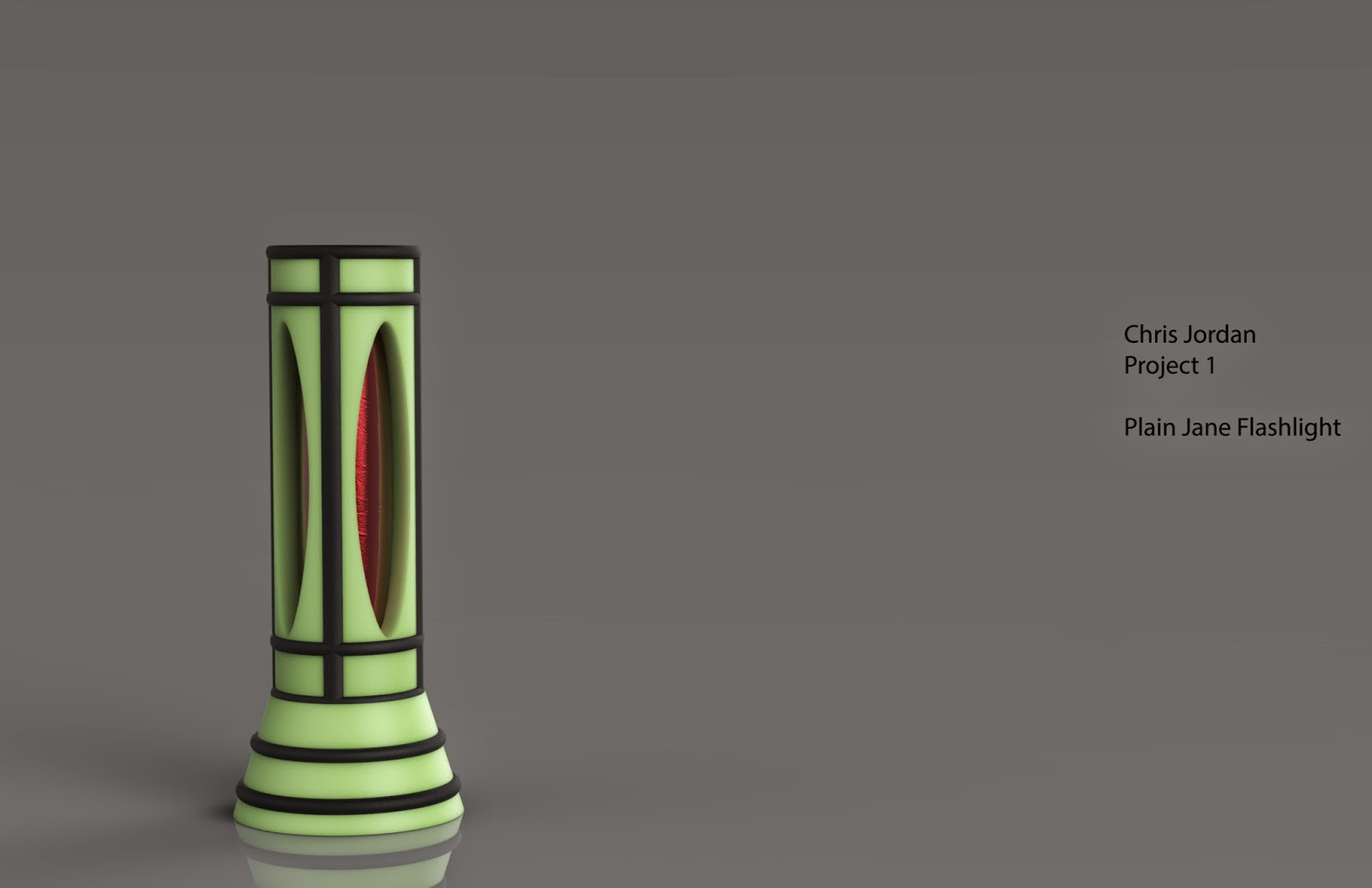

Keyshot #2

At a tilted view this time, the sleeve is standing upright, showcasing the rubber grip, metal shaft, and cut-away notches that are featured.