For week 12, I continued to build on the idea for my geometric lamp.

After last week, I had finalized my idea and began to get the design ready for Laser Cutting.

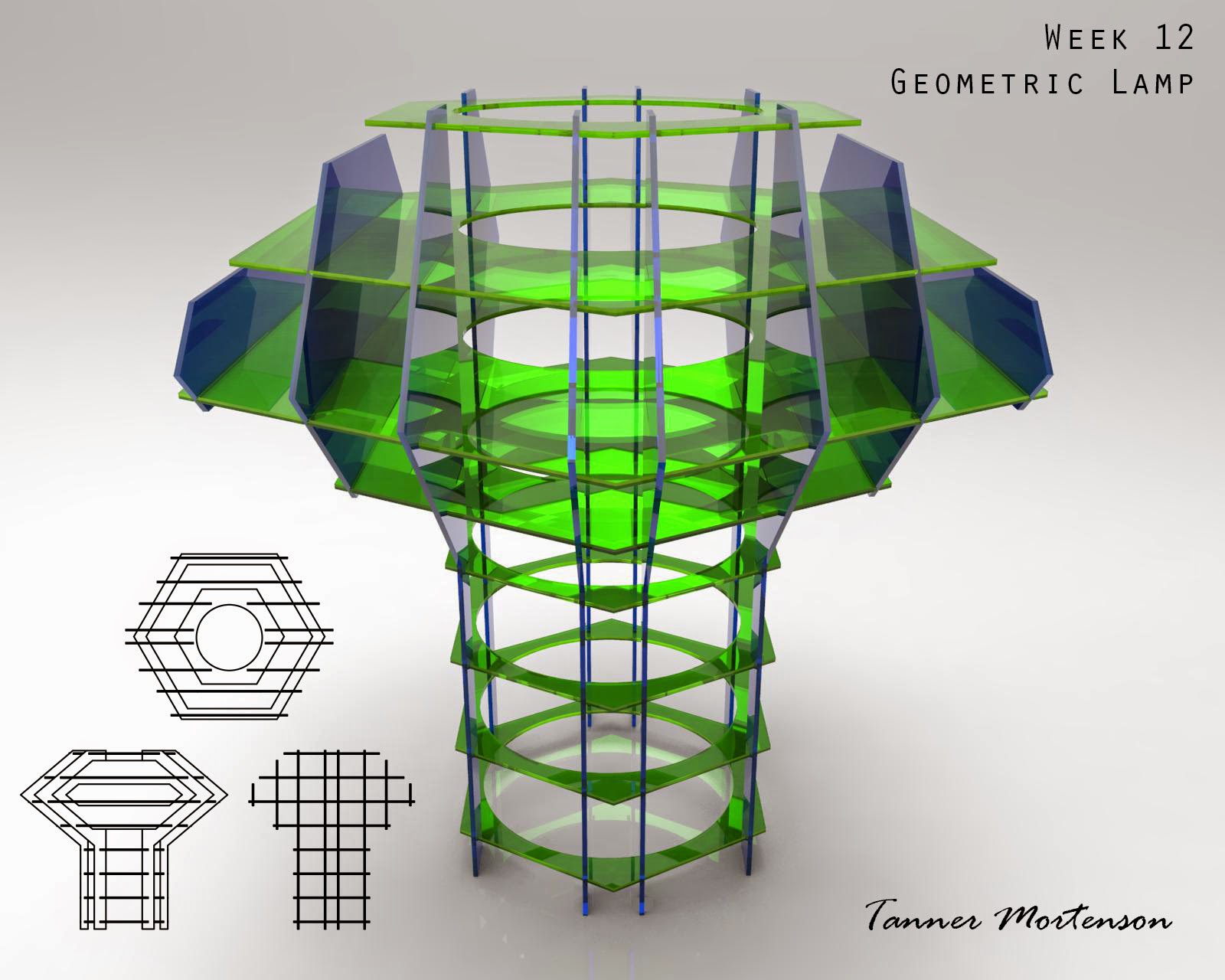

Once the design was finalized, I used two helpful scripts within Rhino- "Cut My Ribs" and "Massive Unroll". Cut My Ribs allowed me to select the different oriented pieces, and then allow the program to automatically cut slots into each piece upon their intersection. Next, Massive Unroll allowed each of those individual cut pieces to be laid out cleanly so I could then arrange them on my cutting sheet.

I chose to use a 30x36 sheet of plexiglass to make my lamp out of, purchased from Home Depot.

In addition, I had to get another small piece of plexiglass to account for the excess pieces that were unable to fit on just one sheet.

I decided to choose the thinner plexiglass sheets to reduce the overall weight of the lamp. Looking back, I would have loved to know silicone was not the best adhesive for this project, as it turned greasy and was not clear as I had hoped it would be. It was also very flexible still when dry, so the structure of the lamp was very shifty.

The light was placed in the middle of the upper portion of the lamp, allowing light to not only be projected left to right and out of the top, but also downward in an ambient fashion.

This unique direction of light is one of the reasons I chose this design.

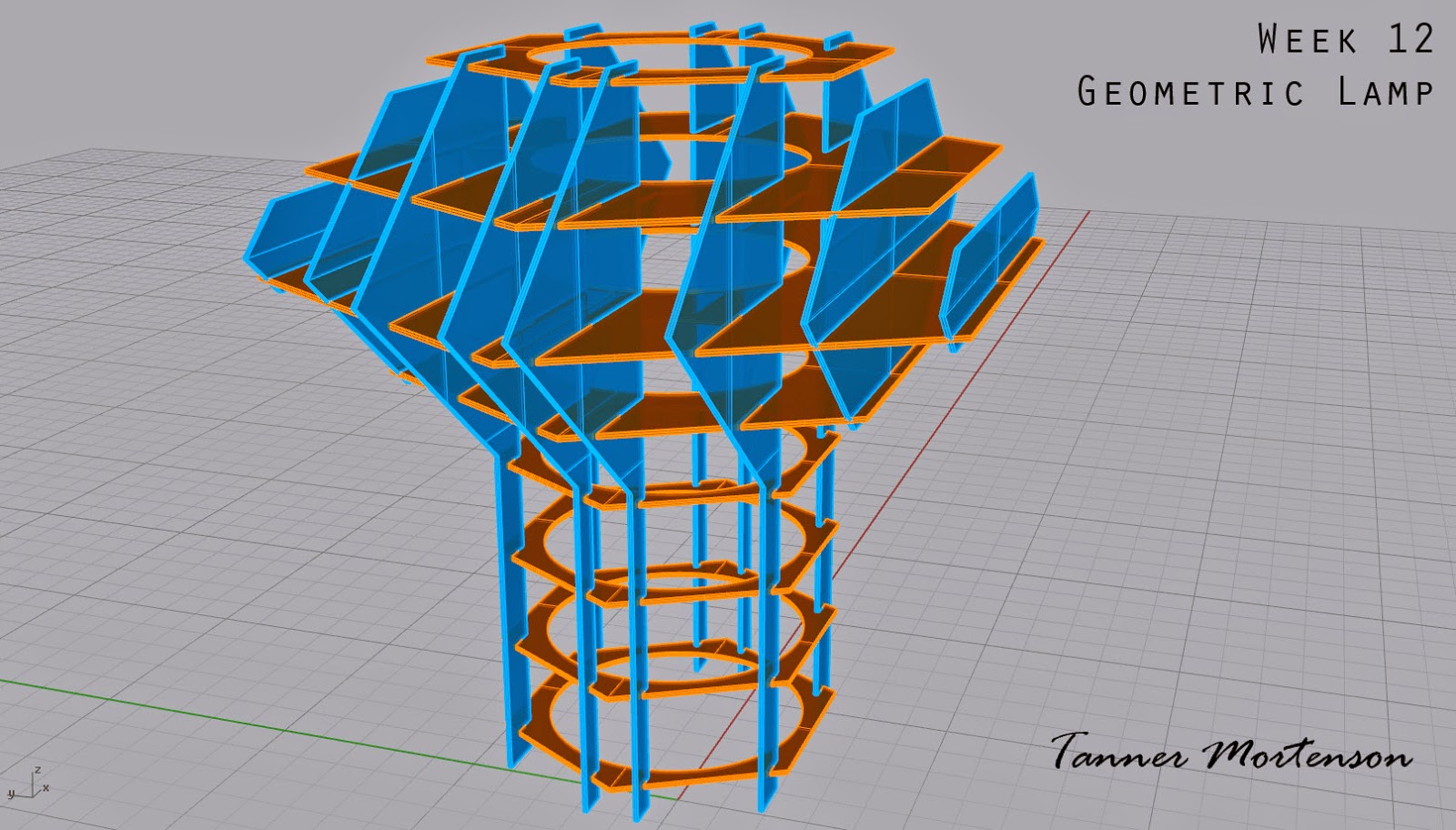

Rhino model screenshots:

Laser Cut sheet design and layout:

Keyshot Renderings:

Final Product:

Light on:

At rest on a stool.