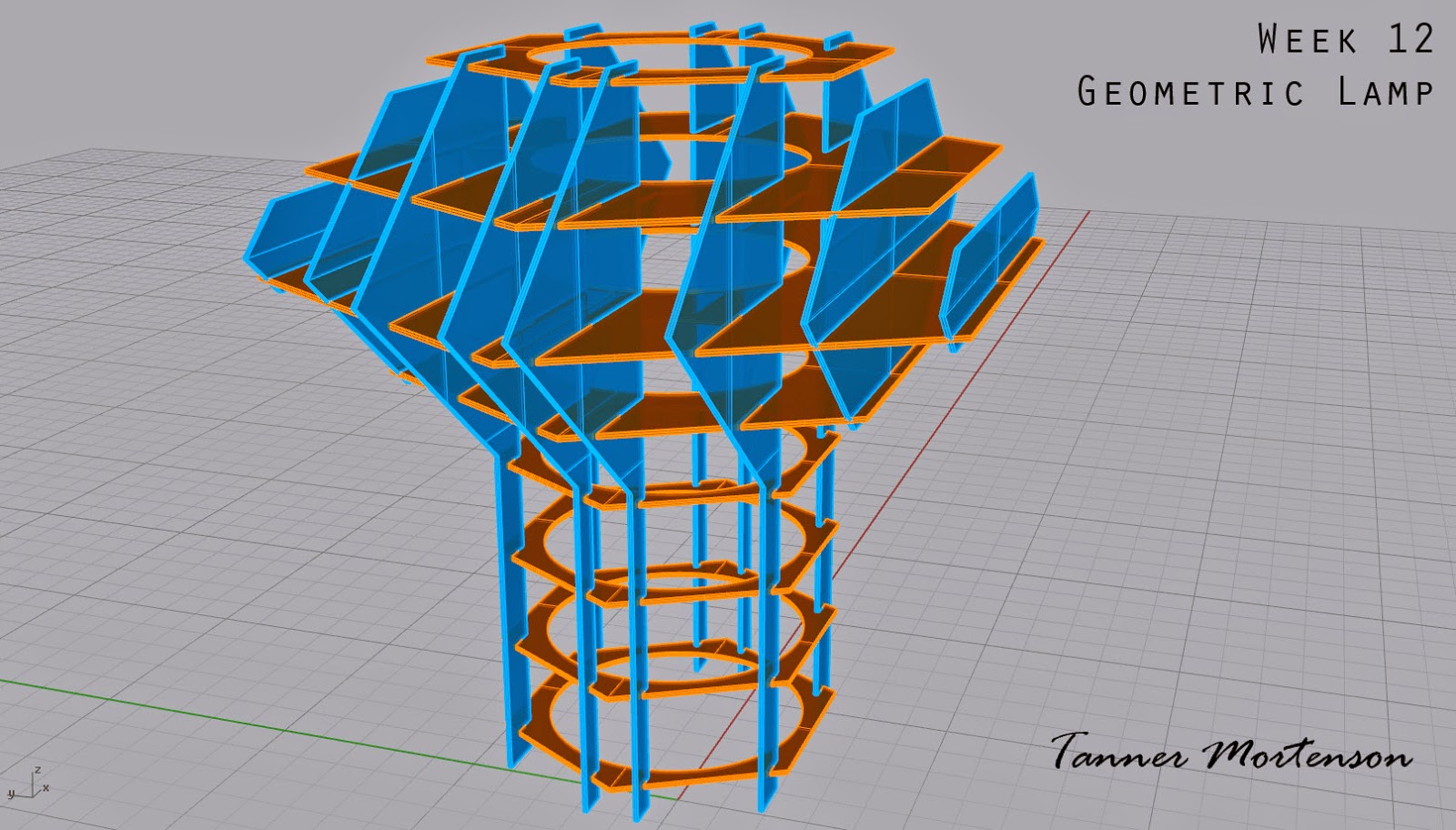

Ghosted Black

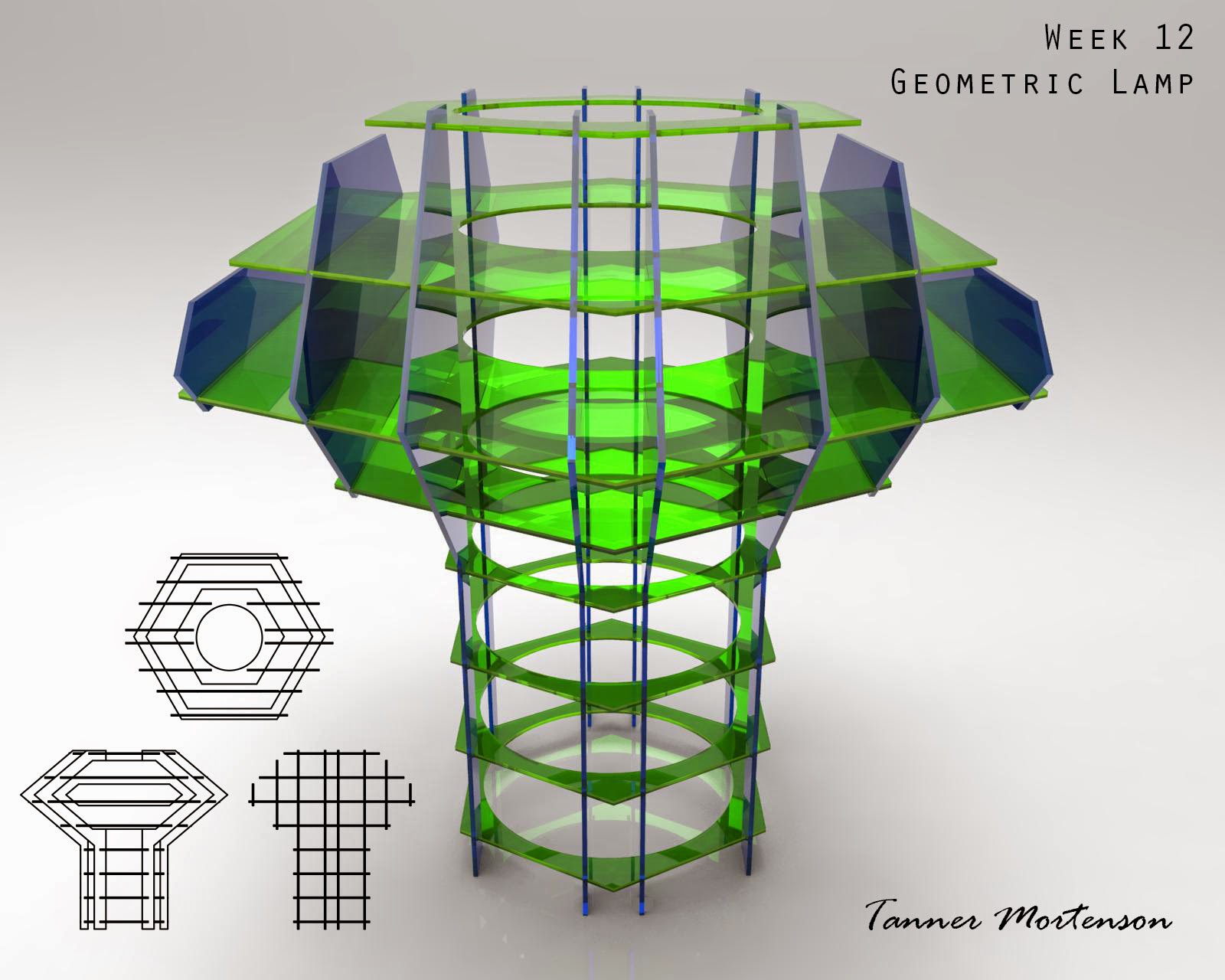

Ghosted Colored

Concept:

I have a lot of fun doing architecture. I got all my inspiration from playing The Sims for 17 years. But this program is nothing compared to the building tools in that game so it's more of a challenge here. I really liked Jay Gibson's castle from another school. Last time I wanted to create a house on a cliff, but I had no idea how. After I had done some minor studying of Mr. Gibson's work, I learned how. Also, I'm quite fascinated with old architecture, and I did one of my favorite styles (Modern) last time, so I wanted to attempt another this time around (Roman). Gothic would be fun someday, but all that detail would ruin me. I still need practice before then. Anyways, I like the idea of buildings dangling off a cliff or built into the cliffside, so that's what my theme is here (again). This was my inspiration image for a cliff. It's cool that those cliffs have water below. Also, it happens to have a beach, so that's a huge win too!

Modeling Techniques:

I needed to know how to make some Roman architecture, so I looked a bunch of images on google. There weren't too many that I focused on. I did find a good tutorial on digital tutors that used this image to make columns. I watched 16 out of 27 tutorials on how to do that, so I spent a stupidly long time with this model. Everything I learned in the tutorials I did with this model. I remember move, scale 1D, scale, sweep1, sweep2, Array, ArrayCRV, Revolve, FilletEdge, FlowAlongSRF, BlendSRF, BooleanIntersect, BooleanDifference, BooleanUnion, BooleanSplit, What, Cap, Project, ProjectToCPlane, setPT, insertEditPoint, explode, group, join, ExtendSRF, ExtractSRF, polyline, controlpointcurve, arc, 3pt Rectangle, 3pt Circle, Ellipse, editPoint, Point on/off, trim, zoomwindow, pictureframe.

The best way to explain how I used a majority of these were creating an object from curves. Using revolve or arrayCRV, either exploding it and manipulating the control-points or I extruded the surface. I used curves, angle and sweep1/2, pipe, setPT, and BooleanDifference for most of the column stuff. I spent a majority of mine time Extruding, moving, and changing control points.

Roman Column Reference

Keyshot Detail of Columns

Materials:

There were a lot of materials. All the dark grey colored materials were used for details: The railing. The windows. The door frames. The unique wall decoration on the right long corridor (in the ghosted colored image those are the pink colored objects)

The floor of the main building was the more yellowish grey on the 2nd row down middle The marble Tan to the right of that are the doors. The 4th row, 1st material is the color of the columns. The human skin in the top row center is the sand. And the one to the right of that is the water.

Materials

.jpeg)

.jpeg)