I decided to make a hexagramic pyramid.

Showing posts with label Sean Lenox. Show all posts

Showing posts with label Sean Lenox. Show all posts

Monday, December 15, 2014

Sunday, December 14, 2014

Blake Artesi & Sean Lenox: Project 8 - Pepakura Chess Piece

Week 15:

Our chess piece is based off of a guitar shape, as Blake was inspired by the bass guitar hanging on Sean's wall. The design boils down to a guitar-shaped bishop, symbolizing a devotion to music.

Our chess piece is based off of a guitar shape, as Blake was inspired by the bass guitar hanging on Sean's wall. The design boils down to a guitar-shaped bishop, symbolizing a devotion to music.

The side pieces are based off the body of a guitar.

We used edge loops and extrusions to create the "horns", and extruded out the neck and top, scaling and extruding upward.

Wednesday, November 26, 2014

Sean Lenox: Project 6 - Lamp

Week 11:

The design for my waffle lamp was inspired by dice and numbers - my original idea was to come up with some kind of numerical notation with rectangles and circles and create an alien die of sorts. I felt that such details would ultimately be lost in the waffle process, however, so I settled for a simpler circle/rectangle pattern inscribed on each side. I'm considering leaving one of the radial slices out to give the lamp a "front" where more light shines through.

I created boxes and spheres and used the Difference command to cut indentations into the box.I also used the difference command to cut the cylinder out of the middle.

The design for my waffle lamp was inspired by dice and numbers - my original idea was to come up with some kind of numerical notation with rectangles and circles and create an alien die of sorts. I felt that such details would ultimately be lost in the waffle process, however, so I settled for a simpler circle/rectangle pattern inscribed on each side. I'm considering leaving one of the radial slices out to give the lamp a "front" where more light shines through.

I created boxes and spheres and used the Difference command to cut indentations into the box.I also used the difference command to cut the cylinder out of the middle.

Week 15:

Here are some photos of the assembled waffle lamp.

Sunday, November 2, 2014

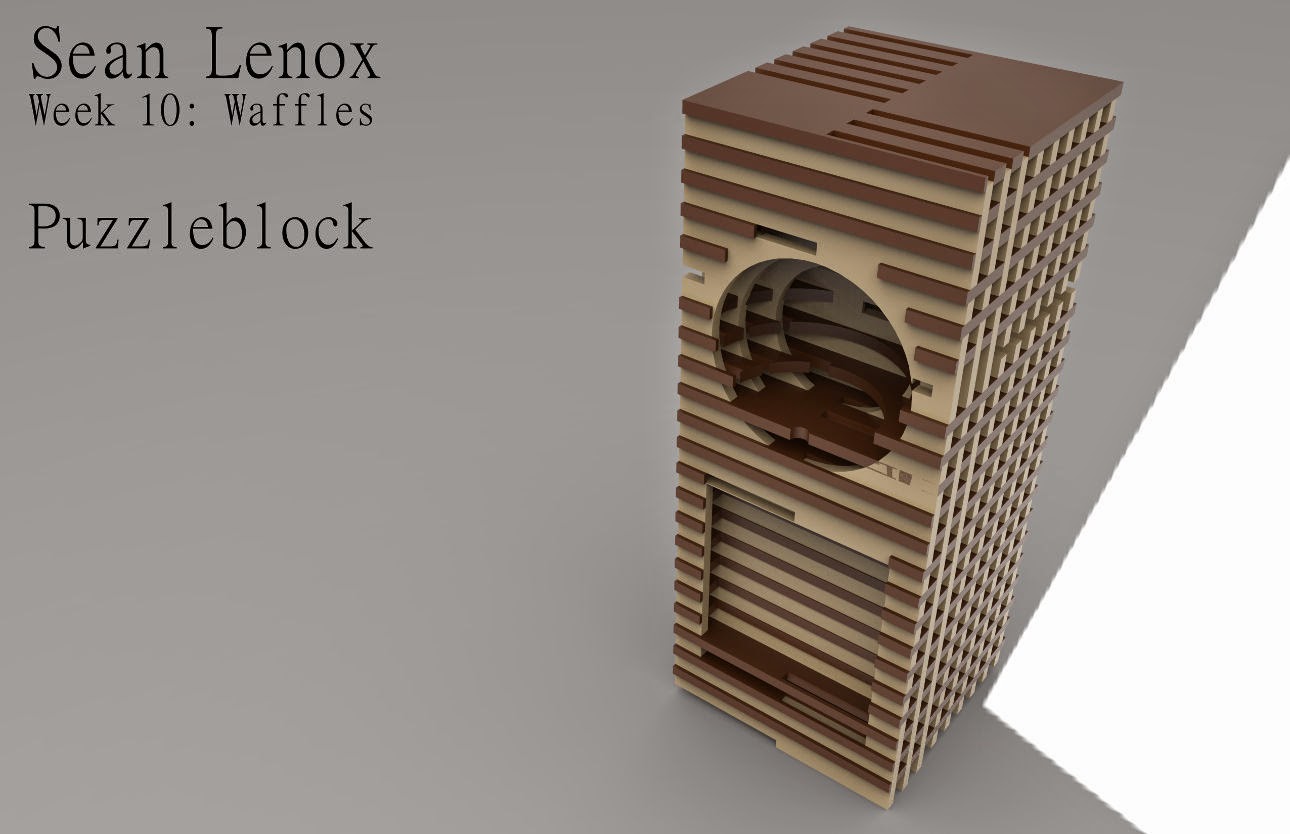

Sean Lenox - Project 5: Waffles

My waffle object for this week is what I call the "Puzzleblock". I was inspired by jigsaw puzzles and block puzzle games like Tetris when making it, as it is a block piece that could theoretically be part of a puzzle or in a puzzle game. I'm exploring sort of a paradoxical theme with it, as it is a puzzle piece that solves itself - the depressions on the back are filled by the pieces on the front. However, because there is only one of it, it is impossible to solve (unless, I suppose, you cut it in half or something), making it an almost frustrating piece of geometry for me.

It is a very simple model: a simple cube with rectangular and spherical holes cut out of one side with a Boolean Difference. I then did another, opposing Difference to cut the block out of the shapes, giving me half-shapes to stick on the other side of the block.

The Cut My Ribs script did some strange things to the waffle pieces, fitting the notches on them in strange, sometimes alternating orientations. After examining the waffle structure, however, It seems that despite the strange notches, everything fits together correctly. I really like the look of the notches and feared messing up the waffle structure by trying to make them more orderly, so I left them the way they are. If they end up not fitting together perfectly, I'm a big dummy.

It is a very simple model: a simple cube with rectangular and spherical holes cut out of one side with a Boolean Difference. I then did another, opposing Difference to cut the block out of the shapes, giving me half-shapes to stick on the other side of the block.

The Cut My Ribs script did some strange things to the waffle pieces, fitting the notches on them in strange, sometimes alternating orientations. After examining the waffle structure, however, It seems that despite the strange notches, everything fits together correctly. I really like the look of the notches and feared messing up the waffle structure by trying to make them more orderly, so I left them the way they are. If they end up not fitting together perfectly, I'm a big dummy.

Week 12: Redo

I decided to spruce up the design of the Puzzleblock a bit, adding more shapes and slots on the sides.

Week 13:

Here are some photos of the assembled Puzzleblock.

Sunday, October 26, 2014

Sean Lenox - Project 4: Slots

Week 9:

Here are my slots, laid out and ready for laser cutting. When putting these together I couldn't help but think of TV remotes, so I made them chunky rounded rectangles with engraved "buttons". This could be because we've been having tons of trouble with our own remote over the past week or so and I just can't get it out of my head.

Something like this, y'know?

I used circles and lines to draw the body, and used a rounded rectangle for the center hole. I used polar arrays and mirrors to get the notches in the right places, and plenty of offset curves for my engravings, also using circles and lines for those. CurveBoolean brought everything together nicely.

I tried to save this as an .stl file, but Rhino just tells me "No surface objects to export." and doesn't save it. Hopefully this isn't a big problem - I have the .3dm file with me. It's still a confusing, though, considering I was able to save my slice sheet as an .stl with no problems. People on the Internet just called it a "bug". Hopefully it will still work.

Week 13:

Here is a photo of the laser-cut slots.

Week 15:

Here is a photo of my slot composition.

Friday, October 3, 2014

Sean Lenox - Project 3: Serial Form

Week 6:

For my laser cutting project I decided to use my flashlight, as Prof. Scott said it would work well. I chopped the engines off the sides because I was afraid they would be difficult to cut, so this Hyperspace Rocket Light isn't quite as Hyperspace. Funny enough, it's actually hard to tell the model is sliced when looking at the Keyshot renders.

For my laser cutting project I decided to use my flashlight, as Prof. Scott said it would work well. I chopped the engines off the sides because I was afraid they would be difficult to cut, so this Hyperspace Rocket Light isn't quite as Hyperspace. Funny enough, it's actually hard to tell the model is sliced when looking at the Keyshot renders.

I used wood materials when rendering these, as I felt they looked fairly close to cardboard.

My concerns are that the model might be too small for laser cutting (I have quite a bit of space left on my sheet, as you can see) and that my cores are incorrectly placed. The hollow design of the flashlight left me a bit confused as to where to place my cores, so I hope they'll work where they are.

Week 6 cont. (10/05/14): Resize and re-slice

I scaled up the flashlight and filled in the inside so it's no longer hollow. I cored it through the middle this time and redid the slice sheet.

It is now much easier to tell that the flashlight has been sliced - the button and rivets look much different now, for example.

Thank you Mr. Scott for getting back to me and telling me how to fix the problems. Please let me know if anything else needs fixing!

Saturday, September 27, 2014

Sean Lenox - Project 2: Flashlight Sleeve

A friend of mine introduced me to the polar array, which led to me sticking shapes all over the flashlight and polar arraying them around it. As I added shapes to my flashlight it started looking pretty silly, so I started modeling it to look like a kids' toy. Showing it to Blake in class I remarked that it looked like "a rocket ship," and he suggested I add some jet engines to the sides. One Keyshot render later, we have a pastel rocket ship-esque toy flashlight.

I used bright, plasticy materials to give it a toy-ish look. I stuck with the default Keyshot background, as I felt it offered the best lighting and made the model easy to see.

I am unsure if the engines are secured enough for printing or if they'll just break right off. I used the gray cylinders to secure them to the body more, so hopefully they'll be safe for printing. Apparently, there are also some naked edges inside the sleeve. I might have to find a way to fix these.

Week 6: Shapeways confirmation

Neither the weird shapes nor the naked edges were a problem! My sleeve has been confirmed and will be printed and shipped shortly.

Week 7: I'm a big idiot

Upon looking at my fellow classmates' sleeves and receiving my own, I have come to the awful conclusion that my sleeve is twice the size it should be. Apparently there was more to this model than just following that flashlight tutorial. Upon revisiting the week 4 folder, I discovered a file containing guidelines for the dimensions the flashlight sleeve should actually have. I slapped my model in there and resized it, fixing the naked edges and giving it the proper dimensions.

Uploading this new model to Shapeways reveals that it costs a much more modest 40 dollars. It's a shame I already ordered the other one.

I'm trying to see if I can get this printed at the school tech store in time for the midterm. If I can't, I might just bring it later to show that I did in fact realize my mistake and print a new one. In the meantime I'll bring the giant one to class tomorrow and we can all laugh at it. I might pack some tissue paper in there to bring the flashlight up, or something. Goodness gracious.

Week 8: The 2nd print

The re-print of the correctly-scaled flashlight is finished! Here are some photos (I had this one printed at the Tech Store on campus).

Saturday, September 6, 2014

Sean Lenox - Project 1: M101 Tank Destroyer

Week 1:

Here is my current progress on my model. I'm making a World War II-type tank, based on the M10 "Wolverine" used by the United States.

I played a lot of Company of Heroes last year, and gained an appreciation for WWII tanks - my hope is to one day have a nice little collection of tank models on a desk somewhere. I've simplified the shapes and design for this model, one as a precaution (I have no idea what kind of models the 3D printer can handle!) and two because I'm not an experienced Maya modeler by any means. I'm honestly surprised I was able to put together something vaguely tank-shaped.

I used some simple rectangles and stretched and squashed them to make the shapes, using plenty of extrusions like a good Maya modeler. The barrel is simply an extruded cylinder stuck into the top of the tank. The treads are the most complex shapes, consisting of short cylinders extruded inward and outward behind some cut, stretched rectangles.

I'm not too sure about object intersections - is it alright if an object is going inside another object, or do all the of the junctions need to be perfectly clean? The wheels are just kind of jammed up against the treads, for example.

Good luck to you all, my fellow modelers!

-Sean

Week 3: Shapeways confirmation

We're off to the printers! Just got word from Shapeways that my tank has passed review and will soon be printed. I hope everything goes well.

Here is my current progress on my model. I'm making a World War II-type tank, based on the M10 "Wolverine" used by the United States.

(reference image)

I used some simple rectangles and stretched and squashed them to make the shapes, using plenty of extrusions like a good Maya modeler. The barrel is simply an extruded cylinder stuck into the top of the tank. The treads are the most complex shapes, consisting of short cylinders extruded inward and outward behind some cut, stretched rectangles.

I'm not too sure about object intersections - is it alright if an object is going inside another object, or do all the of the junctions need to be perfectly clean? The wheels are just kind of jammed up against the treads, for example.

Good luck to you all, my fellow modelers!

-Sean

Week 3: Shapeways confirmation

We're off to the printers! Just got word from Shapeways that my tank has passed review and will soon be printed. I hope everything goes well.

Week 5: Keyshot Renders

For the colors/textures on the tank I wanted to keep things pretty simple. I went with a classic army green-esque color for the body, and added some plastic color accents to give it a model or toy kind of look. I like this Keyshot background as I feel it creates the look of the sun shining in through haze, like a dusty battlefield.

Week 13:

Here are some photos of the printed tank.

Subscribe to:

Posts (Atom)